Need barcodes for your products? Here’s How It Works

Barcodes have undoubtedly made life easier for merchants. Yes, most places used a similar structure even before barcodes. But then everything was manual. And this increased the number of errors. Then there was no guarantee of accuracy.

But we’ve come a long way since then. And if you want to make sure your business is running smoothly and there are no glaring bugs, getting barcodes for your products is beneficial. But first you must learn more about them.

How Food Barcodes Were Invented

Interestingly, barcodes have been around for quite some time. They were introduced as early as 1948 by Bernard Silver and Normal Joseph Woodland. The goal was pretty simple. They wanted to make it easier to read product information during checkout. And reduce errors too.

The prototype originally used UV ink, but it didn’t work. But like all other successful entrepreneurs and visionaries, they didn’t let that discourage them either. They tried again and used the structure of the surly code to create a barcode.

An incandescent light bulb was shown above the drawing to read it through the paper. This is because the black lines in the code absorb light while the white parts show through and are therefore detected.

The Evolution of Barcodes: How They Work Now

Naturally, barcodes have changed since then. And things have changed quite a bit. Scanners are now available to read these codes. The pattern is detected using a laser sent by the scanner. Some of the light from this laser is absorbed and some is reflected, allowing the scanner to read the barcode.

If you want to receive barcodes for your products, you must understand what do the numbers mean. How do brand owners come up with these codes?

It’s actually quite simple. Usually barcodes consist of twelve digit numbers. They are printed below the product to make things easier for everyone. Here’s how the numbers represent a particular product.

- The first digit indicates the type of product and is usually denoted by the numbers 0, 1, 6, 7, or 8.

- The next 5 digits indicate the manufacturer’s code. This is a unique code designed to identify the distributor or manufacturer of the product.

- The next five digits are the product code, unique to each product.

- And the last number is a computer check digit designed to check the correctness of the barcode.

Purpose of the Barcode

Keep in mind that there are many types of barcodes, of which UPC is the most commonly used. Most brands prefer to use barcodes as it makes it easier to visually encode information that can be read by a scanner. Hence, it saves valuable time. Think about it. How long does it take to enter numeric data? Inventory management is a pretty colossal task. Fortunately, barcodes make this task easier.

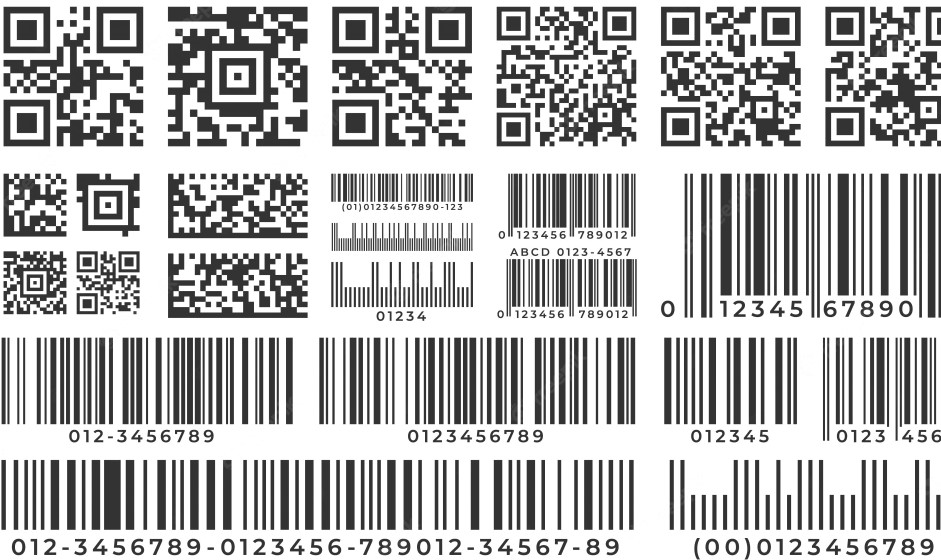

The two main types of barcodes include

One-dimensional (1D) barcodes

These barcodes, presented as a series of black and white stripes, carry a lot of brand information. With this code, you can find out about the product type, color and size. This code is present at the top of the product packaging and proves to be very useful for tracking packages during shipping.

2-dimensional (2D) barcodes

It’s a little tricky. And this is because it carries more information. It reports the stock level of a product along with the price. Indeed, it may even show you a picture of the product.

How barcodes for your products can be useful

There’s a reason why most companies use barcodes these days. This simplifies the delivery and tracking of goods. In addition, inventory management also becomes more convenient with these codes. You can keep a clear and accurate record of the amount of products you have in stock using barcodes.

Interestingly, the barcode is used in a wide variety of industries, including grocery retail, clothing, and even healthcare. Now it is impossible to even imagine how troublesome shopping would be if it were not for barcodes. Want to know more about its benefits? Let’s take a look!

Guaranteed Accuracy

The barcode simplifies the processing of product data. If the seller enters all this data manually, he not only takes more time, but also risks making a mistake. This is not something you need to worry about with barcodes. Everything is digital, so there will be no errors.

Real-time data within your reach

As we have already explained, barcodes help process information at an incredible speed. Therefore, you won’t have to wait long to get your sales or stock levels. All information will be available to you as soon as possible.

No training required

The best thing about implementing barcodes for your products is that you don’t have to spend time teaching your employees how to use them. The scanner does not require any complicated steps. All they have to do is point and click on the code. Yes, it’s that simple!

Better manage your inventory

Improved data accuracy will help you keep a better eye on your inventory and sales. It will also allow you to pre-order items if needed in a timely manner.

cost effective

Barcodes really don’t cost you much. They are quickly generated. Therefore, you will be able to increase the efficiency of your company without overly increasing the budget. And the increased accuracy and data will definitely help you better manage your operations!