Process of Laser Marking and It Advantages

What is Laser Marking?

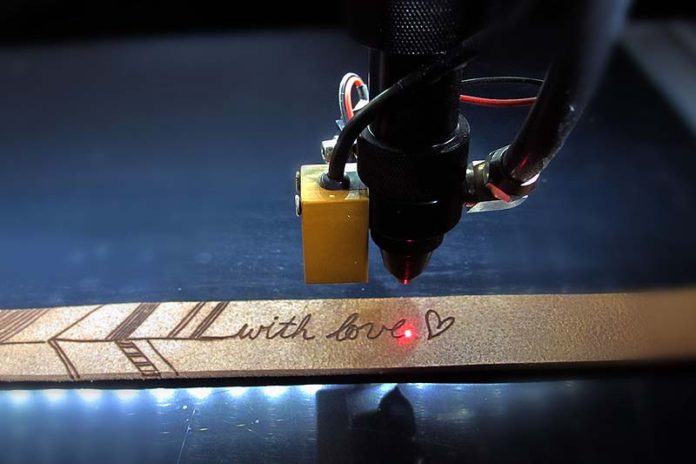

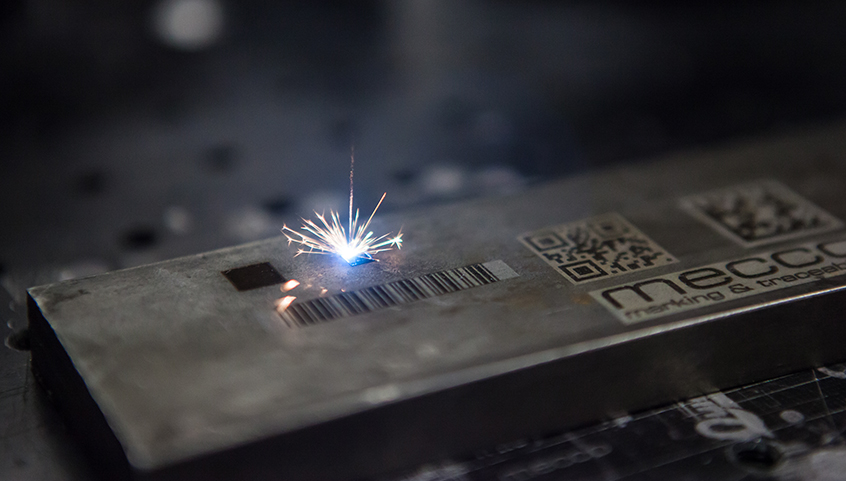

Laser Markingis the process of using laser beams to etch an object. Basically, laser Marking is a more generalized term for various techniques to mark an item, including heat engraving (with a laser), foil stamping, etching with UV light, die cutting, and embossing. For example, when a die is made and fed with a laser beam, it causes the material in the die to etch into the surface that it passes through. The procedure that is done to etch metal is called die cutting and it’s used in a variety of applications including metal stamping, machine tool engraving (for drilling, riveting, etc.)

Engravings are made of a number of materials. Metal can be etched by using different types of lasers, as well as heat, light, ultraviolet, ultrasonic, and carbon dioxide lasers. The laser beam can also be applied to plastics, ceramics, wood, paper, or other objects. When a laser beam is used to etch the metal, the laser causes chemical reactions within the metal, which causes the metal to react with the air it is in.

Advantages of Laser Marking

If you are considering the laser marking of plastic products, there are many advantages to consider. In this article, we will look at these advantages in detail and then look at the advantages of other techniques which are often used in the production of plastic products. The plastic marking process is called adhesives marking, and it can be used for products such as toys, stickers, decals, stickers and many other uses. We look at some of the advantages and disadvantages of using this process to mark your plastic products.

One of the most popular advantages of using this technique is that there is no need to re-mark products which have been cut, broken or otherwise damaged by another method. This saves you time and therefore money. Laser marking involves a process which involves the use of an ion beam (which is essentially a high energy beam of light) to permanently mark the surface of a product.

The laser beam is then passed onto the plastic product, Metal Product and Wooden Product and the product’s coating is exposed to the beam of light, which permanently changes the colour of the plastic product. This is because the laser beam alters the colour of the product’s coating, by emitting the right colour of light. Once the marking process is complete, the product can be cleaned thoroughly with the help of a detergent, before being re-marked.

Although a number of companies use the process of adhesives marking in the production of plastic products,

One of the advantages of laser marking in the production of plastic products is that there is no need to re-mark items after they have been cut or broken. This means that all of the items made with the use of this process can last longer than the original ones. This can also save a lot of money on maintenance and cleaning costs.

The above information should help you understand the advantages adhesives marking in the production of plastic products. There are a number of benefits to making use of this technique in the production of plastic products,